Ejma Bellows Software Synthesizer

Bellows vendors will often quote two different cycle lives for their bellows. One is in accordance with ASME B31.3, Appendix X. The other is in accordance with the Standards of The Expansion Joint Manufacturers Association. The latter provides a significantly higher cycle life. The EJMA bellows fatigue curve is a best fit curve based on data that was available, so it provides an expected average cycle life. The ASME curve was developed also using bellows fatigue data, but it provides design margins consistent with ASME pressure equipment codes.

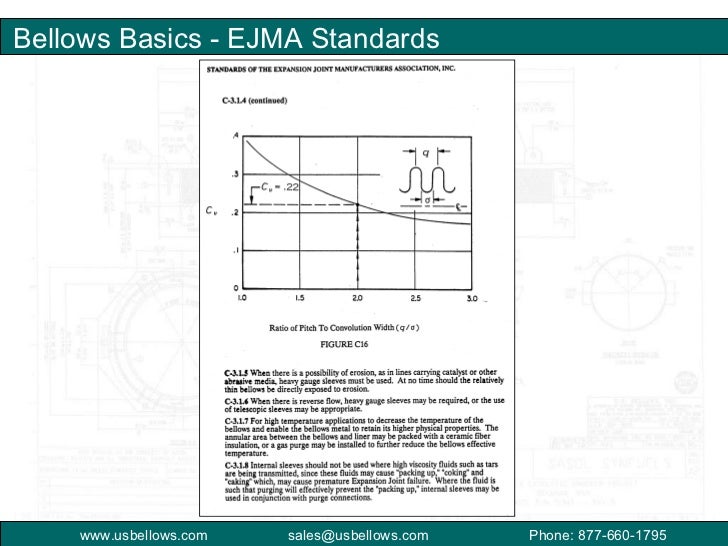

EJMA-The Expansion Joint Manufacturers Association, Inc. Triad Bellows Design and Manufacturing uses bellows design software based on EJMA 10th edition guidelines. Displayname field missing from registry need for speed 2015 xbox. EJMA Calculations for t=.03, w=1.095, q= 1.0 inches. Bellows Calculation Software. The Expansion Joint Manufacturers Association, Inc. Is an organization of established manufacturers of metal bellows type expansion joints. EJMA was founded in 1955 to establish and maintain quality design and manufacturing.

Historically, designers have put large factors of safety on the number of design cycles for bellows, which was in part justified since there was no design margin in the EJMA fatigue curve. This would result in a margin of safety entirely dependent upon the designer, and could vary from large, to none. This was not a satisfactory condition for an ASME Code, so I developed the fatigue curve with safety factors that was put in ASME B31.3 Appendix X. When using this curve, it should be recognized that appropriate design margins are already included, and they should not also be included in the specified number of cycles.

With bellows, design for an excessive number of cycles can unnecessarily compromise other design aspects, such as design with respect to internal pressure and column stability (resistance to squirm). There is ongoing work to potentially revise the EJMA fatigue curve to include a factor of safety, which may be variable. This would be a very good development as it will lead to more uniform design practices and less confusion.

Software belajar jawi tadika purifier. When such a fatigue design basis is provided in the EJMA Standards, then it is very likely that the fatigue curve in Appendix X of ASME B31.3 will be removed, and ASME B31.3 will simply refer to the EJMA fatigue design rules, and may specify the required design margin if the revisions to the EJMA rules include a variable design margin. Becht, Fellow ASME, former Chairman of the ASME B31.3, Process Piping Code, is a recognized authority in pressure vessels, piping, expansion joints, and elevated temperature design.

He has more than 30 years of experience in design, design review, analysis, check-out, mechanical integrity, development, troubleshooting, and failure analysis. He is an ASME Fellow and has more than 60 publications and five patents and is a frequent speaker and chairman in technical forums. He received the ASME Dedicated Service Award in 2001 and was the recipient of the 2009 ASME and the 2014 J. Hall Taylor Medal. He is President of Becht Engineering Co., Inc, CEO of Helidex, LLC, and Director/Owner of Sonomatic Ltd.